- Contact Person : Mr. Hua Gaoyun

- Company Name : Jiangyin Xinhai Science And Technology Co., Ltd.

- Tel : 0086-510-86869638

- Fax : 0086-510-86402205

- Address : Jiangsu,Jiangyin city,A0139,No.3,East Chengjiang Road Jiangyin City

- Country/Region : China

- Zip : 214400

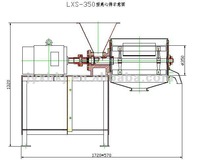

Rotary screener

FTS Series Rotary Screener

The machine is a kind of classification screener for solid granules, to be matched with the operation of medical powder line or to be operated as single machines. It has the features of reliable technical performance, smooth running, low noise and easy operating, etc. The machine is suitable for the material screening in the processing of the medicine, chemicals and foodstuff in high viscosity, high fibrin and high mesh with an ideal result. It is composed of machine base, chassis, material screwing in/out devices and motor, etc. A sift structure is equipped in the cylinder in which the target materials were turn up and down continuously by the scraper to push the materials forward until the fine material is drop from sieve. The others are pushed ahead continuously until to be sent out from the exit for coarse materials.

| Model | Model 190 | Model350 |

| Capacity(kg/h) | 100-1500 | 200-1800 |

| Number of mesh | 20-200 | 20-200 |

| Speed of principal axis(r/min) | 940 | 960 |

| Motor power(kw) | 2.2 | 5.5 |

| Weight(kg) | 200 | 380 |

| Overall size (L×W×H)(mm) | 1680×620×1380 | 1850×800×1540 |

FTS Series Rotary Screener

The machine is a kind of classification screener for solid granules, to be matched with the operation of medical powder line or to be operated as single machines. It has the features of reliable technical performance, smooth running, low noise and easy operating, etc. The machine is suitable for the material screening in the processing of the medicine, chemicals and foodstuff in high viscosity, high fibrin and high mesh with an ideal result. It is composed of machine base, chassis, material screwing in/out devices and motor, etc. A sift structure is equipped in the cylinder in which the target materials were turn up and down continuously by the scraper to push the materials forward until the fine material is drop from sieve. The others are pushed ahead continuously until to be sent out from the exit for coarse materials.

| Model | Model 190 | Model350 |

| Capacity(kg/h) | 100-1500 | 200-1800 |

| Number of mesh | 20-200 | 20-200 |

| Speed of principal axis(r/min) | 940 | 960 |

| Motor power(kw) | 2.2 | 5.5 |

| Weight(kg) | 200 | 380 |

| Overall size (L×W×H)(mm) | 1680×620×1380 | 1850×800×1540 |

Rotary screener